Welcome to our guide on maximizing efficiency by implementing MRP systems effectively! Managing production and resources can be a complex task, but with the right systems in place, it can become much more streamlined. MRP systems help businesses plan and organize their manufacturing processes, ensuring that materials are available when needed and reducing excess inventory. In this article, we will explore how businesses can implement MRP systems successfully to optimize their operations and achieve higher levels of efficiency.

Understanding the Basics of MRP Systems

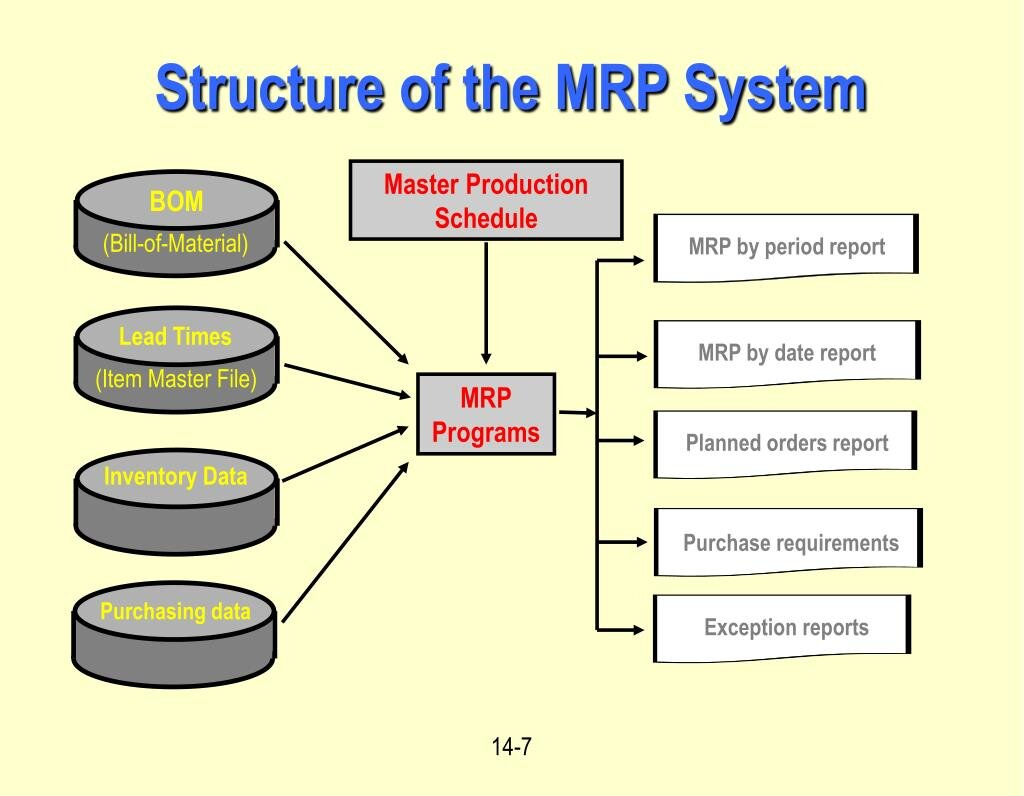

MRP systems, or Material Requirements Planning systems, are software solutions that help businesses effectively manage their inventory, production schedules, and procurement processes. These systems use a variety of inputs, such as inventory levels, sales forecasts, and lead times, to generate material requirements and production schedules. By automating these processes, MRP systems can improve efficiency, reduce costs, and ensure that businesses have the right materials at the right time.

One of the key components of an MRP system is the bill of materials (BOM). The BOM is a list of all the components and quantities needed to assemble a finished product. This information is used by the MRP system to calculate the material requirements for each product, taking into account factors such as lead times and order quantities. By accurately calculating material requirements, businesses can avoid stockouts, minimize excess inventory, and optimize production schedules.

Another important aspect of MRP systems is the master production schedule (MPS). The MPS is a plan that specifies the quantity of each finished product to be produced in each time period. By aligning the MPS with the demand forecast and available inventory, businesses can ensure that they are producing the right products in the right quantities at the right time. This can help businesses meet customer demand, reduce lead times, and minimize production costs.

In addition to BOM and MPS, MRP systems also use inventory records and purchase orders to calculate material requirements. Inventory records provide information on current stock levels, on-hand quantities, and reorder points, while purchase orders specify the quantity and timing of material deliveries. By analyzing this data, MRP systems can generate accurate material requirements plans that meet production schedules and minimize inventory costs.

One of the advantages of MRP systems is their ability to automate and streamline the planning and procurement processes. By using algorithms and calculations based on historical data and forecasting techniques, MRP systems can generate material requirements plans quickly and accurately. This can help businesses reduce the time and effort required to plan production schedules, order materials, and manage inventory levels.

Overall, understanding the basics of MRP systems is essential for businesses looking to implement these systems effectively. By knowing how MRP systems work, what components they use, and how they can benefit a business, organizations can leverage these tools to improve efficiency, reduce costs, and optimize their production processes.

Selecting the Right MRP Software for Your Business

Implementing an MRP system in your business can greatly improve efficiency and streamline operations. However, choosing the right MRP software is crucial to ensure success. There are several factors to consider when selecting the right MRP software for your business.

First and foremost, you need to assess your business needs and requirements. Consider the size of your business, the complexity of your manufacturing processes, and the number of users who will be using the software. It’s important to choose a software that is scalable and can grow with your business.

Another important factor to consider is the compatibility of the MRP software with your existing systems. Make sure the software can seamlessly integrate with your accounting, inventory management, and other software systems. This will ensure a smooth transition and prevent any disruptions to your business operations.

It’s also important to consider the level of support and training offered by the MRP software provider. Look for a provider that offers comprehensive training programs and ongoing support to help you get the most out of the software. This will ensure that your employees are properly trained and can effectively use the software to its full potential.

Additionally, consider the cost of the MRP software and any associated fees. Make sure to get a clear understanding of the pricing structure, including any additional costs for implementation, training, and support. It’s important to choose a software that fits within your budget while still meeting your business needs.

Another important consideration is the usability and user-friendliness of the MRP software. Choose a software that is intuitive and easy to use, as this will help increase user adoption and maximize the benefits of the software. Consider asking for a demo or trial period to test out the software and see if it meets your needs.

Lastly, consider the reputation and track record of the MRP software provider. Look for reviews and testimonials from other businesses who have used the software to get an idea of the provider’s reliability and customer satisfaction. Choose a reputable provider with a proven track record of success in the industry.

By carefully considering these factors, you can select the right MRP software for your business and ensure a successful implementation. Remember to involve key stakeholders in the decision-making process and take the time to thoroughly evaluate your options before making a final decision. With the right MRP software in place, you can streamline operations, improve efficiency, and take your business to the next level.

Training Employees on MRP System Usage

Implementing an MRP system in a company can bring about a lot of positive changes in terms of efficiency and productivity. However, in order for the system to work effectively, employees need to be properly trained on how to use it. Training employees on MRP system usage is crucial for ensuring that the system is utilized to its full potential.

One of the key aspects of training employees on MRP system usage is to provide them with a comprehensive understanding of how the system works. This includes familiarizing them with the various modules and functions of the system, as well as teaching them how to input data, generate reports, and analyze information. Employees should also be given hands-on practice with the system so that they can become comfortable using it in a real-world setting.

It is important to tailor the training program to the specific needs and knowledge levels of the employees. For example, employees who are already familiar with MRP systems may only require a refresher course, while those who are completely new to the concept may need more intensive training. By customizing the training program to suit the needs of the employees, companies can ensure that they are getting the most out of their MRP system.

Another important aspect of training employees on MRP system usage is to provide ongoing support and guidance. Even after the initial training program is completed, employees may still have questions or need help with using the system. Companies should have a dedicated support team or help desk in place to assist employees with any issues that may arise. This ongoing support is essential for ensuring that employees feel comfortable and confident using the system on a day-to-day basis.

In addition to providing comprehensive training and ongoing support, companies should also incentivize employees to use the MRP system effectively. This can be done through performance bonuses, rewards, or recognition programs for employees who demonstrate proficiency in using the system. By offering incentives, companies can motivate employees to engage with the system and make the most of its capabilities.

In conclusion, training employees on MRP system usage is essential for maximizing the benefits of implementing such a system in a company. By providing comprehensive training, ongoing support, and incentives for employees, companies can ensure that the MRP system is effectively utilized. Ultimately, the success of an MRP system hinges on the knowledge and proficiency of the employees who use it, so investing in training programs is key to achieving long-term success.

Integrating MRP Systems with Existing Processes

When implementing MRP (Material Requirements Planning) systems into your existing business processes, it is important to remember that this is not a standalone solution. Integration is key to ensuring the success of your MRP system. Here are some important steps to take when integrating MRP systems with your existing processes:

First and foremost, it’s crucial to start by thoroughly understanding your current business processes. This includes your inventory management, production scheduling, and purchasing processes. By having a clear understanding of how your business operates, you can tailor the MRP system to best fit your specific needs.

Next, communicate with all departments within your organization to ensure that everyone is on board with the implementation of the MRP system. This includes getting buy-in from key stakeholders such as production managers, inventory controllers, and purchasing agents. By involving everyone in the process, you can address any concerns early on and ensure a smooth transition.

It’s also important to assess the capabilities of your current IT infrastructure. Make sure that your hardware and software are capable of supporting the MRP system, and if not, invest in the necessary upgrades. This will help prevent any technical issues that could hinder the effectiveness of the MRP system.

Another critical step in integrating MRP systems with existing processes is to train your employees on how to use the new system. Provide comprehensive training sessions for all users, from the shop floor to the boardroom. This will help ensure that everyone understands how to input data, generate reports, and make decisions based on the information provided by the MRP system.

Furthermore, it is important to establish clear communication channels between departments to ensure that all data is accurate and up to date. This can include regular meetings between production and purchasing teams to review inventory levels and production plans, as well as implementing automated alerts within the MRP system to notify users of any potential issues.

Lastly, continuously monitor and evaluate the performance of the MRP system to identify any areas for improvement. Regularly review key performance indicators such as inventory turnover, on-time delivery rates, and production efficiency. By proactively addressing any issues that arise, you can ensure that the MRP system remains effective and continues to support your business processes.

By following these steps and taking a proactive approach to integration, you can effectively implement an MRP system that seamlessly integrates with your existing processes and drives efficiency and profitability throughout your organization.

Monitoring and Evaluating the Effectiveness of MRP Implementation

After implementing an MRP system in your organization, it is crucial to monitor and evaluate its effectiveness to ensure that it is delivering the expected results. Monitoring the system involves tracking key performance indicators (KPIs) such as on-time delivery, inventory turnover, lead times, and order accuracy. These KPIs will give you insights into how well the MRP system is performing and whether it is helping to streamline operations and improve efficiency.

One way to monitor the effectiveness of the MRP system is to conduct regular audits and reviews of the system. This can help identify any issues or bottlenecks that may be hindering the system’s performance. By analyzing the data and feedback from employees, you can make necessary adjustments and improvements to optimize the system’s functionality.

In addition to monitoring the system, it is essential to evaluate its impact on the overall operations of the organization. This evaluation can involve conducting surveys or interviews with key stakeholders to gather feedback on how the MRP system has changed their workflow and processes. Understanding the perspectives of employees who interact with the system on a daily basis can provide valuable insights into its efficiency and effectiveness.

Another way to evaluate the effectiveness of the MRP system is to compare the actual performance metrics against the projected outcomes. This can help you determine whether the system is meeting its intended goals and objectives. If there are discrepancies between the expected and actual results, it may be necessary to reassess the system’s configuration or implementation strategy.

Furthermore, ongoing training and support for employees are crucial for ensuring the successful implementation and utilization of the MRP system. By providing training sessions and resources, you can help employees understand the system’s functionality and maximize its potential benefits. Regular communication and feedback sessions can also help address any issues or concerns that may arise during the implementation process.

In conclusion, monitoring and evaluating the effectiveness of an MRP system is essential for ensuring that it is contributing to the success of your organization. By tracking key performance indicators, conducting regular audits, and gathering feedback from stakeholders, you can make informed decisions about the system’s performance and make necessary adjustments to improve its functionality. Through ongoing training and support, you can empower your employees to make the most of the MRP system and drive operational excellence in your organization.

Originally posted 2024-04-25 02:57:45.